The Ultimate Air Compressors Guide - Air Compressor Explained

Shopping for an air compressor can be very daunting if you’re not familiar with the jargon that is used. With so many varied options and styles of compressors available in the market, it's understandable that you would be confused.

With all this in mind, we've created this ultimate air compressor guide that will go into detail of the many important features a compressor has, as well as answering any questions you may have about things you need to consider when buying one.

Once you've read this guide please take a look at our How To Choose The Correct Air Compressor guide, which will walk you though which compressor you need depending on what you want to do with it.

Contents

- What is the function of an air compressor?

- What types of air compressors are there?

- Which air compressor is quietest?

- Are air compressors dangerous?

- What CFM compressor do I need?

- Is higher CFM better air compressor?

- What is the difference between CFM and SCFM?

- What does psi mean on an air compressor?

- How long does it take for air compressor to build pressure?

- Can I use an air compressor indoors?

- How long do air compressors last?

- Can air compressors get wet?

What is the function of an air compressor?

To put it simply, an air compressor compresses air, stores it and then delivers it to which ever tool is being used. Air compressors can use either an electric motor or a gas/petrol engine for power, depending on the type of compressor you have.

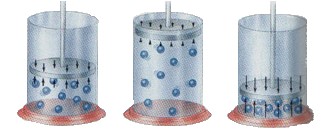

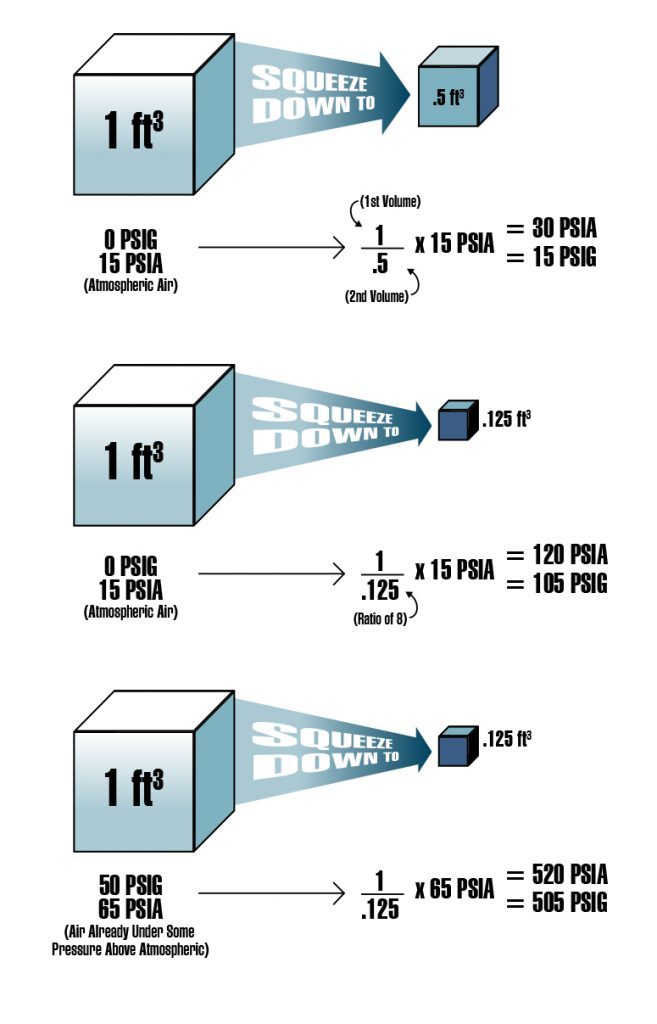

The compressor sucks in volumes of air and compresses (squeezes) it in a restricted tank, increasing its pressure by making the volume smaller. It then transfers the high-pressure air to a another receiver tank.

Air compressors can range in size from small portable compressors that can fit in a glove-box for inflating tires to giant reciprocating or turbo-compressor machines found in pipeline service, and everything in between. Air compressors have a wide range of uses in numerous industries, however we know them as typically being used for for powering air tools.

What types of air compressors are there?

Air compressors fall into two different groups: positive displacement and dynamic.

Reciprocating Compressors

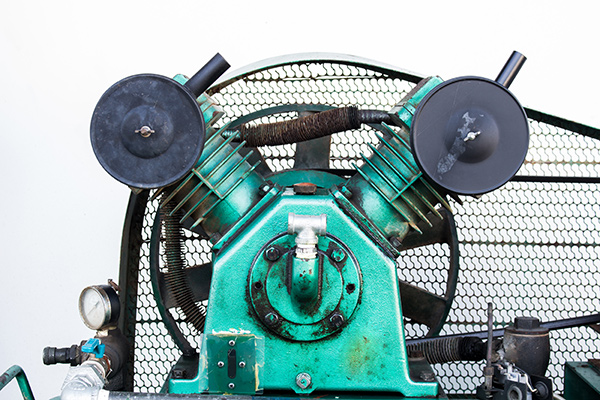

To make the volume of the cylinder smaller, a Reciprocating compressor uses a piston to increase air pressure. Because of this, they take in repetitive volumes of air which is then confined within the closed space creating a higher pressure.

Reciprocating compressors are the most common type available and can be used in DIY and professional settings. You can view our range of reciprocating air compressors here.

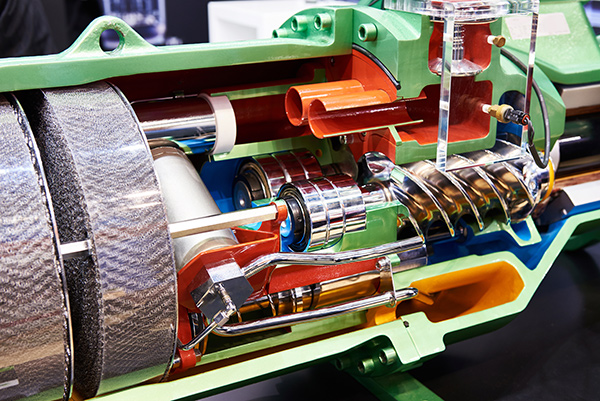

Rotary Screw Compressors

Rotary screw compressors force the air into the cylinder using rotors, while the size is continuously being reduced. This process uses oil filters that must be replaced regularly. The oil is used throughout for lubrication, sealing, and heat absorption. Before any usable air exits the chamber, the oil must be removed.

Dynamic Compressors

Dynamic air compressors pressurise the air by using rotating impellers which accelerate and decelerate the air. The deceleration of the air creates an increase in pressure. Some compressors are completely oil-free to allow use in highly sensitive environments.

Centrifugal Compressors

Centrifugal air compressors use an array of stages that continuously compress and cool the air as it flows through the machine. Air is drawn into the impeller and accelerates as it travels outward. The kinetic energy is then changed into potential energy by using a diffuser to slow the flow down. Centrifugal compressors also boast being able to run continuously with low maintenance requirements.

Which air compressor is quietest?

Regardless of the environment you're using your air compressor in, it's easy to assume you don't want to have a machines that makes a massive amount of noise. Loud compressors can be very uncomfortable for workers, customers and the operators alike, especially if around it for long periods of time. Noise levels of air compressors range on average between 40 and 92 decibels. The lower the decibel the quieter the machine will be, making for more comfortable working.

Unfortunately with larger more powerful machines, noise will follow. There can be a few factors that you should look out for when trying to determine how noisy your air compressor will be.

Intake

The intake point is probably the nosiest part of the air compressor. It is also one of the main components where changes cannot be made in an attempt to quieten the machine. Like a vacuum cleaner, the air compressor sucks air in to the machine to operate and this makes a loud noise while doing so.

Friction

Friction is caused by moving parts, and the more moving parts the more friction that is created. This will ultimately generate more noise. As such if you have a reciprocating compressor, it will emit more noise, meanwhile a rotary compressor can have as little as one moving part, meaning it will give off considerably less noise.

Power Source

An electric compressor will obviously be the quietest option. If your compressor is powered by gas or petrol, you essentially have an engine attached to the compressor. The engine will be the main source of noise.

Vibration Noise

Vibrations shouldn't create too much to noise pollution from an air compressor. Nevertheless, because they are are repetitive and constant throughout use, it can seem as though they cause the most noise. Vibrations can be caused from the structure of your compressor, where it has been placed and if it has many shallow or hollow parts.

Materials

The material your compressor is made of is pretty self explanatory in regards to noise. If the air compressor is made of higher quality materials it will be thicker, sturdier and denser. Lower quality materials may be rather thin and allow more noise to escape.

Are air compressors dangerous?

In short, yes. Not that this in any way, shape or form should deter you from buying one. As with any and all tools and machinery you could ever use, it has it's dangers if not used correctly. So rather than exploring if they're dangerous, we'll look at how you can ensure your safety while using it.

Risk: Rupture

Ruptures are the most prominent danger you face with an air compressor. If compressor vessel is subjected to excessive amounts of pressure or damaged it can cause the container to rupture and possibly explode.

Solution

Your air compressor should come with an instruction manual and warning labels, read them and take note of what is considered a dangerous level of pressure. The compressor will have a safety release valve and a regulator that will prevent the compressor over pressurising. Both parts should be inspected, maintained and replaced as per the user manual. The safety release valve should be checked each time the compressor is used.

Check the safety cut off valve is working correctly - pull on the ring to release air. When you release the ring the air should stop. If the valve does not operate correctly do not use the compressor.

Any damage to the pressure vessel will also require the compressor to be removed from service and inspected by a suitably trained technician.

Risk: Overheating

An overheating air compressor is the main cause of failure. Your air compressor overheating can be the result of internal factors, external conditions and sometimes both. Through out the cycle, the air that has been suctioned into the machine becomes hot as a result of the being compressed, though it swiftly cools before it reaches the endpoint. However, if there isn't sufficiently cooling it can cause the compressor to overheat.

Solution

If the compressor has not been cleaned and maintained correctly then dirt build up on the compressor and the motor heat sinks will cause the air compressor to overheat.

Keep your compressor clean and ensure the cooling fins on the pump are free from obstructions and dirt. A high compression ratio, typically caused by low suction pressure, is another problem that can cause an air compressor to overheat. Check for obstructed or dirty air filters, improperly fitted couplers and air hoses and faulty gauges.

Inadequate space around the compressor can also cause overheating. Ensure that any vents and intakes are not obstructed or facing directly against a wall.

Risk: Oil Leak

Many air compressors contain oil chambers that enable the machine to run smoothly and to keep the moving parts lubricated. If you notice an oil leak from the compressor do not use the compressor until it has been thoroughly checked over.

Solution

Check if the compressor has been overfilled with oil. The oil should be in the middle of the red dot of the sight glass. If there is too much oil drain some away by removing the sump plug bolt. Next identify where the oil is actually leaking from. It could be from the piston chamber or from the oil chamber.

Simple to identify - you will see the oil leak with your naked eye as soon as it starts, so inspect your compressor often to be safe! After you have figured out the cause and the leakage point the compressor may need disassembling and a gasket or seal replacing.

Risk: Physical Harm

It has been known for compressed air to enter the blood stream through a break in the skin or through a body opening. An air bubble in the blood stream is known medically as an embolism, a dangerous medical condition in which a blood vessel is blocked, in this case, by an air bubble. An embolism of an artery can cause coma, paralysis or death depending upon its size, duration and location. While it is rare, the risk is still VERY serious business, and should not be taken lightly.

Solution

Never turn the hose or tool you're using towards your own or anyone else's body. Always wear suitable clothing, such as long sleeved tops and trousers, wear ear mufflers, gloves and safety goggles. It's also important to ensure that anyone who will be using the air compressor follows these rules and is well trained on how to sensibly use it. An air compressor is a tool, not a toy, and should be treated as such.

What CFM compressor do I need?

CFM stands for Cubic Feet per Minute and is the volume of air your compressor can pump out per minute. When trying to determine how much CFM you need, start by asking yourself these key questions:

What tools and equipment will it be supporting?

Will it be supporting more than one user’s needs?

Each individual air compressor has a max CFM output that it can generate. The CFM output must be more than the tool requirement, so that each tool will operate efficiently and without problems in continuous use. As a general rule, if you're running a tool that needs 5 CFM at 90 PSI, your compressor CFM should offer an output at least 1.5 times larger than that. And if you have 2 technicians using wrenches at the same time, calculate 1.5 times the required CFM of all tools added together.

If the tool is to be used continuously for long periods of time, such as a polisher, spray gun or sander, then the compressor should be specified with a larger tank and CFM output. This prevents the compressor motor having to run continuously to keep up with the tool and extends the life of the compressor.

Please read our How To Choose The Correct Air Compressor guide for more info.

Does a higher CFM mean a better air compressor?

Cubic feet per minute is the volume of air being delivered by the compressor to the air tool. This number is used as a measure of the compressor’s capabilities — and it’s one of the most important ratings when choosing an air compressor. Compressors with higher CFM ratings provide more air, which makes them suitable for tools and equipment that require a higher volume of air to operate.

However a higher CFM certainly does not make it a better air compressor, it simply makes it more powerful. If your tools only requires a small CFM then spending additional money on a high CFM rating isn't necessary. Many brands offer compressors of various CFM ratings, each one offering the same quality machine but at different powers. A good air compressor is determined by a myriad of factors, CFM ratings just being one of them.

What is the difference between CFM and SCFM?

The most common air compressor ratings are CFM (Cubic Feet per Minute) and SCFM (standard cfm). So, what exactly is the difference?

CFM is measured at the actual conditions (actual pressure, actual temperature). The distinction between SCFM and CFM is important because air density changes with pressure and temperature. So the actual CFM will vary with how high above sea level the compressor is and the temperature.

SCFM stands for Standard Cubic Feet per Minute, with “Standard” implying standard conditions that the CFM reading is taken.

What does PSI mean on an air compressor?

PSI stands for pound per square inch. It is considered to be the unit of measurement for pressure, measuring how much force is applied to a certain area. As you know, air compressors essentially squeeze the air down like you may squeeze a spring. Similar to the limit on how much you can squeeze a spring with your bare hands, there is a limit to how much your air compressor can compress the air. That limit is translated as the PSI rating.

For every air tool, you'll require a variation of pressure and flow-rate. For example inflating a bicycle tyre may require a relatively high pressure, but a low flow-rate (because the tyre has low volume). A blowgun, however require little pressure, but a considerable flow-rate, as you want to move a large volume of air.

How long does it take for air compressor to build pressure?

The time it takes for an air compressor to build pressure will differ as no two models are exactly the same. The greater the CFM the quicker the compressor can pump air into the tank. The larger the tank the more air needs to be compressed to fill it. Typically you will find that it shouldn't take any longer than 2-5 minutes.

Most standard DIY compressors are advertised as 8 bar or 115 psi, and are set at this pressure when you buy them. But if you only ever need say 5 bar it’s better to lower the pressure by altering the cut off valve . This means the compressor has less work to do to squeeze the air down in the tank.

Can I use an air compressor indoors?

Petrol or gas powered compressors cannot be used indoors. The fumes and exhaust can seem harmless when used outside, however inhaling fumes in a confined space can seriously put your health at risk.

One of the most desirable aspects of the electric air compressor is that they produce an excellent quality of compressed air without emitting carbon or exhaust fumes, therefore allowing them to be used indoors. They tend to be smaller and lighter than petrol powered air compressors since they don't have a combustion engine attached to them, making them easier to carry from room to room for DIY work.

How long do air compressors last?

When it comes to complex tools such as air compressors the only way you can guarantee a long life, regardless of brand, is if you can keep up with regular maintenance and checks. Be sure to check each part regularly as per the maintenance schedule.

Most air compressors require oil to function smoothly. Oil is important as it works as a lubricant to ensure moving parts do not wear down from too much friction. The oil does however need to be changed regularly or the compressor will lose its ability to lubricate efficiently. It's recommend that the oil is changed after the first 10 hours of use and then checked and topped up every 20 hours of use thereafter. After about 120 hours of use you should drain and change the oil.

It's also important to regularly check that all the fasteners are tightened. If you are constantly using your air compressor, it can loosen any nuts and bolts inside, due to the vibration produced by the engine’s operation. So regular checks will ensure that they're still tight and at the correct torque.

Dust inside the intake vents can cause the engine to overheat and overwork itself. Keep dust out of the intake vents by performing regular maintenance of the air filters and replacing them when required. The air compressors will automatically turn off if the machine gets too hot, or is producing less pressure than is required.

Essentially, air compressors are incredibly tenacious machines. With regular maintenance, reciprocating compressors can have a life expectancy of 10 to 15 years.

Can air compressors get wet?

Is is highly recommended not to get your compressor wet. While you can store your compressor outside, you’ll want to cover it with some type of shelter, as its best not to allow it to be exposed to rain or snow. Air compressors can produce significant amounts of water, which is squeezed from humid air the compressor sucks in through its intake.

If the water is left in the compressor it can seriously damage the components connected to your compressed air system and possibly contaminate your product - as well as causing internal damage to the actual air compressor. In an attempt to minimise the volume of water that finds it's way into system piping, most air compressors have a water separator and trap of some kind. It is important to keep in mind that a wet tank will collect excess moisture and therefore will need to be drained daily to avoid corrosion and rust.

Still need help?

Our in house experts are always on hand for buying advice and to provide bespoke care, regardless of the application.

Call SGS on 01332 576 850 or fill out our contact form today.

Milwaukee Authorised Distributor

Milwaukee Authorised Distributor  4.4 out of 5 with 50,000+ reviews

4.4 out of 5 with 50,000+ reviews  Free delivery on orders over £75*

Free delivery on orders over £75*  Next working day delivery available*

Next working day delivery available*