Air powered tools have been around since the 1800’s and even today, are still being used daily in auto garages and industrial applications. Pneumatic tools are fast becoming recognised as both an affordable and indispensable option to the home DIY-er. A small to medium sized compressor can run a number of pneumatic tools that can help speed up jobs you may need to do around the house or in the garage.

This may sound somewhat intimidating to a newcomer. However, despite pneumatic tools needing some specialist set up, in the long run they can actually save you a great deal of working time and effort. They also afford professional results, speed up auto work and can loosen just about any nut or bolt.

Air tools are handy devices that can be used for a range of jobs in building, automotive and homes. Some of the most common jobs involving use of an air tool include pumping up a bike, car, powering nail guns, blowing debris from construction sites and many other chores. This buyers guide outlines the basics of how air tools work, what tools are available, and how to use them with an air compressor.

How does a pneumatic tool work?

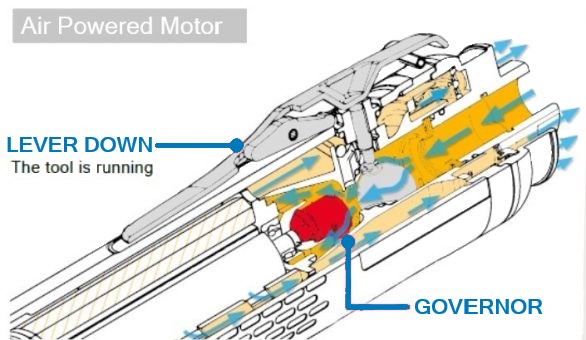

Pneumatic tools are a type of power tool, powered by compressed air, supplied by an air compressor. The air compressor has a gas-powered pump mechanism that continually forces air into a steel container tank until the air becomes pressurised. The pneumatic tool is hooked up to a hose that is attached to the tank via an air valve.

Every pneumatic tool, whether it is a spray gun, ratchet, sand blaster or any other air-powered tool, has a release valve or firing pin. Only when the trigger is pulled on the pneumatic tool, the firing "pin" is opened and thus opens a valve inside the tool and pressurised air flows through the tool. This air will either turn a crank or engine that operates gears (as in a ratchet tool) or course through a barrel to shoot a nail/staple.

What are air tools used for?

Air tools are lightweight, portable, easy-to-use, and can speed up work related to drilling, sanding, painting, or spray painting. They’re also of great use in remote locations that have little to no access to power. Air tools can be used for a variety of applications. Almost any tool that you can buy battery or mains powered, you'll be able to find an air powered alternative.

- Drills

- Sanders

- Angle grinders

- Saws

- Nail guns

- Chipping hammers

- Spray guns

- Polisher

- Air ratchet

- Impact wrench

- Air gun

- Sand blasting gun

- Air shears

- Pop riveter

- Needle scaler

- Blow guns

What is the difference between pneumatic and electric?

Air tools have a high power to weight ratio. To put it simply, an air tool will be lighter than both cordless battery and mains powered tools of the same power rating. Air tools have simple air motors or pistons which are considerably lighter than an electric motor. This is important for anyone who may be using their tool all day, as obviously a lighter tool will lessen fatigue. Air tools are much simpler and have less working parts than an electric tool, so there is less that can go wrong with inner workings. Unlike electric tools which have a universal motor (it can run on AC or DC) which produces sparks at the brushes in contact with the commutator, an air tool is spark-less, making them much safer. This can be a distinct advantage in hazardous environments where there may be gas or flammable liquids present. Air tools are also quite slim compared to electric tools with their bulky motors, so they can be used in cramped locations (e.g. working on cars).

Are air tools better than power tools?

Since electric and pneumatic varieties of the same tool can be found in most stores, it is quite understandable if the average DIYer gets increasingly confused about which one to buy. Every power tool offers different advantages. Both styles of power tool come with pros and cons. Choosing which tool is best for you should depend on your specific needs for the tool are. There are many different features to consider when making the decision of electric over air power such as cost, power, maintenance, safety, weight and portability. That being said, pneumatic tools are largely considered as industrial grade tools that are meant for heavy-duty repair and construction, and thus, outperform electric tools to a large extent.

Are pneumatic tools intrinsically safe?

The term Intrinsically Safe (I.S.) also known as explosion-proof, is often used generically to describe tools that are ideal for working with in hazardous (particularly explosive) areas. I.S. is a protection concept based around limiting the available electrical energy to nonincendive levels so that sparks cannot occur from short circuit or failures which could cause an explosive atmosphere to ignite.

The term, and precautions, of I.S. tools are guidelines to ensure maximum safety for the user. Electric tools won't cut it as they have the constant spark inside them when running, whereas yes, air tools can be made intrinsically safe, due to lack of sparks.

What size air compressor do I need to run air tools?

When it comes to choosing the right air compressor for your air tools, the larger the air tank your compressor has the better and longer your tool will run at a more consistent CFM. This is because a larger air tank will be depleted less often than a smaller tank. It’s worth investing in a large enough tank to complete the job you have in mind – for example, even though a spray gun will work with a small 6 litre compressor, it will only work in very short bursts. 6 litres would be plenty for spraying the body of a guitar, however if you want to paint a whole car or van, you’d probably want at least a 100 litre air compressor. With that said, going out and buying the biggest air compressor you can find, could leave you out of pocket. If you only plan on using your air tool occasionally, then it may be worth only getting the size you need.

To find the minimum tank size of the compressor you need multiple your tool’s required SCFM by 6.

For example, if you run an impact wrench (8 SCFM):

8 SCFM x 6 = at least a 48 litre compressor tank

To find out more read: How To Choose The Correct Air Compressor.

What is cut in and cut out pressure?

A compressors always has two set-points: the cut-in and the cut-out. These are simply the two pressures at which the compressor starts and stops. The compressor will stop when it reaches the cut-out pressure and will start again when the pressure drops back to the cut-in pressure.

To adjust the pressure remove the black cover from the pressure switch. Turn the adjusting screw anticlockwise to lower the cut off pressure and clockwise to increase the cut off pressure.

What is the difference between PSI and CFM?

Pounds per square inch (psi) is the way we assess how many pounds of pressure are exerted on a single square inch of space — 100 psi equates to 100 pounds of force exerted per square inch. The air gauge on an air compressor displays PSI within the compressed air system.

Cubic feet per minute (CFM) is a measure of volume used to indicate the air compressor’s output rate in terms of cubic feet of air per minute of operation. CFM is measured at a given PSI and increases in direct proportion to the horsepower (HP) that is applied. While small, mobile at-home air compressors may deliver around 8 CFM, industrial air compressors with 200 HP can achieve air flow of around 1,000 CFM at 100 PSI.

Ensuring the successful application of your air tools requires supplying the required CFM and PSI. To do so effectively, air compressor operators must understand the relationship between CFM and PSI.

In a compressed air system, the amount of pressure has a direct impact on the rate of flow. Find out more in our air compressor CFM guide.

What air tools require the most CFM?

All air tools run on different CFM. Even the same style of tool can have different CFM requirements, meaning two different air powered spray guns by the same brand can have different needs. Typically the bigger force the tool requires, the more CFM it will require. For example as a general rule for home improvements and DIY tools, an air sander or sandblaster will require higher CFM requirements than perhaps an nail gun or stapler.

However this can never be a guaranteed science, as every tool is different. If you want to know exactly, you can read the product manual or product specifications for each air tool you're considering. Here we have provided a comprehensive breakdown: What CFM air compressor is need to run air tools.

Still need help?

Our in house experts are always on hand for buying advice and to provide bespoke care, regardless of the application.

Call SGS on 01332 576 850 or fill out our contact form today.