Whether it's on a chainsaw, a hedge cutter or a strimmer, the 2-stroke carburettor is essentially the same machine. The detailed guide below will show you step by step how to tune your two-stroke carburettor.

Rather than just show you how to adjust these two mixture screws here, we're also going to show you what's happening inside the carburettor when you're actually doing the adjusting and how it affects the engine and the air flow going through the carburettor using diagrams.

On the image above you can see your high screw (the little H) and then you've got your low screw (the little L). When you get to these screws on the machine you would need to get a screwdriver and screw these really tight until they can't go in anymore, so that will set them at ground zero, preventing the fuel from going any further.

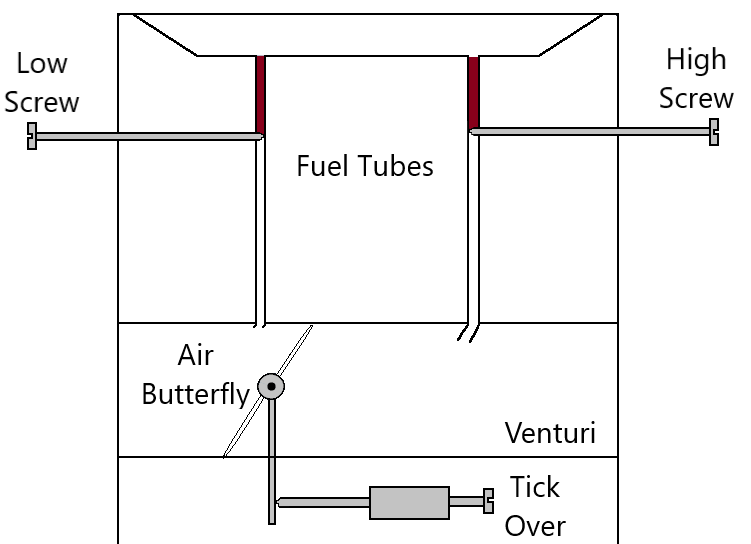

In this diagram you can see the high screw (H) and the low screw (L) and the fuel tubes here that come out into the main jet area and out into the venturi to the engine. The venturi is where the air comes through from the air filter right through and in to the engine. And finally you see the tick over and the tick over screw that pushes on to a special plate that's attached to the air butterfly inside the venturi. The air butterfly is responsible for the amount of airflow that comes through and into the engine, so adjusting the tick over just a little so the butterfly is slightly off its sides of the venturi, creates the best position for efficient air flow.

Here you can see each jet has been turned one full turn. This has opened up the gap ever so slightly willing the fuel to travel down the tubes. If the engine is not on the fuel won't actually be sucked down so much but rather the gap allows it to come down once it is needed.

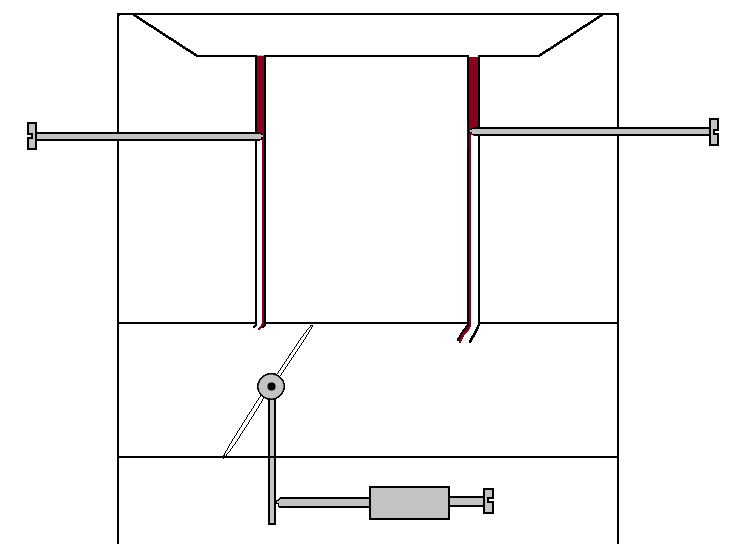

In this diagram below it illustrates that the engine is now running and the throttle trigger has been pressed in full and started the engine.

Now if the mixture screws are set correctly you’ll have a good ratio of air to fuel in the inlet (fuel - red dots, air - blue dots) and the fuel is separated into molecules as it has been atomised by the air rushing in through to the engine, so it’s ready to be burnt in the engine for combustion.

You can tell if the screws need adjusting either out or in by listening to the engine and how its performing. Whether it's performing weak, quite strong or it seems to be choking, the screws can be adjusted to this accordingly, making the mixture either richer or leaner. Riching it up means introducing slightly more fuel, so unscrewing H screw just a quarter of a turn allows more to come down the fuel tube and that of course allows more to be integrated in with the air. Making it leaner, would be to do the same but in reverse, restricting the amount of fuel.

To make the mix even more rich, the screw is loosened almost completely out, allowing a lot of fuel to come through. However for this particular carburettor it is way too much, and as you can see the ratio is not good, as you've got much less air than you have fuel.

What happens is the engine can't cope with this amount of fuel, and will begin lagging, not working at its full capacity. As it won't be doing as many revolutions per minute it won't be drawing as much air and this is when the engine may begin to choke or it can coke up and ruin spark plugs. It won't give any power to the engine

If you screw it in to lean it up a little bit, so there's less fuel coming through, there's a better mix there and the engine will start to pull back and sound a little better. If we keep going and listen carefully we can get the engine sounding it's best, working at its optimum.

At this point this is only working on the H screw, to get the high revs right. It's high revs because the full throttle is open, so the engine actually runs a little revs a little higher when you reduce the amount of fuel and increase the amount of air. Although it revs higher, it doesn't actually give more power, it just seems as though it does. By using the air and the bit of fuel that's available, it doesn't have to try too hard to combust the amount of fuel that's coming through, but it doesn't actually give the best performance in terms of power.

If the engine sounds good, you can assume this side is now sorted. With it nicely working you should now take a look at the L screw (the low screw). Now this is where the low screw comes into its own, firstly as the tick over was adjusted earlier, so that is was slightly off the sides you don't need to hold the throttle anymore because the screw is doing that for you. From here simply adjust the L screw either in or out and listen to the engine as to whether or not it sounds efficient.

In this diagram you can see that the L screw has been opened even more slightly, so there's more fuel coming through. It's important to remember each individual machine needs a different level of fuel to air mixture. It's hard to say this is the right amount of fuel for one so it'll be the right amount of fuel for others. Also different brands of two-stroke oil and whether or not the fuel is fresh will also determine on how you should set the mixture screws to give them a different effect on the engine.

Still need help?

Our in house experts are always on hand for buying advice and to provide bespoke care, regardless of the application.

Call SGS on 01332 576 850 or fill out our contact form today.

How to Choose the Best Strimmer for the Job