Choosing a Mitre Saw

A mitre saw is an essential tool for all sorts of carpentry tasks, whether it’s a project you’re working on at home or in a professional environment. It’s a power tool that allows you to cut at a range of angles and can be used for everything from big tasks such as door frames to smaller jobs like resizing picture frames.

Here at SGS Engineering, we’ve made choosing a mitre saw easy. We’ve got a selection of mitre saws for you to choose from that are designed to suit a full range of cutting jobs.

If you’re not quite sure what this type of saw is used for or you’re asking yourself ‘what size mitre saw do I need?’, allow us to help. This guide will explain all about this useful tool and the different ways it can be used, along with tips to help when buying a mitre saw. Even if you don’t need one immediately, adding one to your toolbox now means you’ll be ready when the time comes.

What is a mitre saw?

Before we look at what this type of saw is, it’s worth understanding its name. A ‘mitre’ in this sense refers to a joint made between two pieces of material – usually wood – at an angle of 90°. The main purpose of this type of saw, therefore, is to create these joints.

Mitre saws explained

Mitre saws (also known as ‘miter’ saws) were originally a manual tool that consisted of a circular saw suspended on rollers. A mitre box, which is a three-sided box that holds the piece of wood in place, was used to help guide the saw and allow it to make accurate crosscuts.

The hand mitre saw has largely been replaced by a power tool version, such as the models available here at SGS Engineering. These power tools do the same job effortlessly and more efficiently. When choosing a mitre saw, this power tool version is the smoothest option.

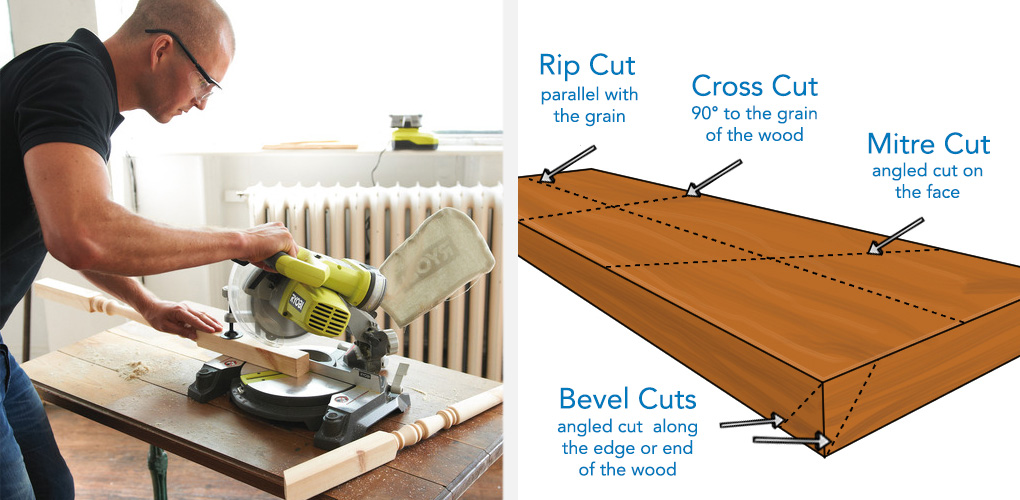

This modern power tool version of the mitre saw pulls a spinning, circular blade down onto and through a piece of wood or workpiece that is held in place, usually at a 90° angle. The angle can be easily changed depending on the desired cut and mitre saws with different blade sizes for various purposes are available.

Why do you need to use a mitre saw?

A mitre saw is a tool that has various applications, but its main use is for making crosscuts and mitres in a workpiece. It’s essential for framing, cutting moulding, and it’s also used to cut door trims, baseboards and crowns to size. From carving out the initial joint to slicing off a small amount to create the perfect fit, mitre saws are the go-to tool for these types of task.

For exterior work, such as putting together garden decking, a mitre saw’s precise cutting action is ideal for areas that require intense accuracy. Mitre cuts are necessary for the corners of most decking. It’s also possible to create bevel cuts with compound mitre saws, and they can also be used on handrails where relevant.

What mitre saw is right for the task?

If you’re wondering how to buy a mitre saw, it’s important you consider the task and where you’re likely to be using it before purchasing one.

To do this, it’s good to know the different types of mitre saw and how to use them. Here, we look at what’s available.

Different mitre saw types

One of the main considerations is what the mitre saw blade size needs to be for the task you’re working on. Knowing what size saw you need will help you to make accurate crosscuts in the wood.

Regular mitre saws deliver a straight cut through pieces of wood and timber. The depth depends on the size of the saw’s blade and those with an adjustable base, such as in the Ryobi line, mean the angle can be changed to suit your needs.

Compound mitre saw

The majority of DIYers will invest in a compound mitre saw as the arm of the saw can easily be adjusted to the left or right, allowing the user to make more complex cuts. This makes them ideal for skirting joints, boxing in and MDF work.

Sliding Compound Mitre Saw

These are very similar to compound mitre saws, however they can also slide out on a rail. Mitre saw rails are useful because they extend the cutting width and allow you to work on larger pieces of wood. They're a great tool for cutting larger material such as worktops, boards, decking and sheet materials.

Corded and cordless

If you’re going to be doing a lot of work with a mitre saw in your garage or workshop at home, a corded saw will be more powerful for working on tougher material. However, for exterior work or on projects where a power source cannot be found, one of the fantastic cordless mitre saws are essential.

What size mitre saw do I need?

As well as knowing the different types of saw that are available, when it comes to choosing your mitre saw, size is important. If you’re asking yourself what size mitre saw you need, you’re on the right track.

You’ll need to run some checks before you buy your saw as getting the size right is crucial. The main question you need to answer here is what job are you working on? This will tell you which size you need.

If you’re using a mitre saw with a larger blade that’s around 305mm (12 inches) or more in size, you’ll find that this can be used for making deeper and wider cuts. Smaller saws that are 254mm (10 inches) or smaller are easier to handle and are better used for smaller, more detailed cutting work.

Here is a quick-look guide to some typical jobs for each mitre saw blade size:

- Laminate flooring

The size of saw you use here depends on the size of the laminate flooring. For larger laminate floors, a 305mm saw could be ideal, whereas smaller areas could benefit from a smaller saw.

You will need to consider how tough the material is here, however. Laminate is strong and hard-wearing so you might need the larger saw to seamlessly cut through the material.

- Skirting boards

A smaller, 254mm saw is ideal for most skirting boards, but if you’ve already got a larger saw, the 305mm blade should be just as capable of making accurate cuts.

- Coving

As with laminate flooring, this very much depends on the size of the material you’re working on. If it’s only around 120mm thick, a smaller 254mm saw is ideal. For coving and cornices that are 250mm thick, you’ll need something more robust like the 305mm blade.

Ultimately, the size and toughness of the material you’re cutting will tell you what size mitre saw you need. The more work you do with this power tool, the more you’ll get to know when different size blades are needed.

How to use a mitre saw safely

Take the time to read the instructions included with your mitre saw before you use it for the first time. Even if you’ve used this type of saw before, no two models are the same, so you’ll need to familiarise yourself with the different settings and functions.

Here are some key safety precautions to follow:

- Wear safety glasses and ear defenders when operating the saw. Make sure you have these ready before you switch it on.

- Keep your fingers six inches from the blade while cutting. Your saw might include lines to show the correct position for your hands while operating it.

- If something falls to the floor while the blade is spinning, don’t reach for it until the blade has stopped rotating.

- Make sure the blade has come to a stop at the end of each cut before you lift it up.

- Remember to unplug the saw when you’re not using it or if you’re changing the blade.

These are some simple safety measures to protect you while using this type of power tool.

Your mitre saw buying guide

So, now you know the different types of mitre saw that are available and have an idea of how to select the right mitre saw blade size for the job, it’s worth having an idea of the different models that are available to buy.

We’ve rounded up some of the top power tools that we stock here at SGS Engineering. Take a look at the range to see what could be the perfect fit.

Milwaukee MS216SB 216mm 240V Slide Mitre Saw

This Milwaukee mitre saw has a 216mm blade that delivers large and accurate cut capacities. Durability and accuracy are achieved through a heavy duty cast base, fence and dual vertical steel rails with linear bearings that create a smooth sliding action.

It also has a powerful frameless motor that delivers 6,000rpm, providing fast cutting power for the user. Plus, to cut lines perfectly and quickly, this mitre saw is fitted with an adjustable laser, which helps to achieve perfect and quick alignment lines.

It has a 48°/-2° bevel capacity and a release system for quick and smooth change of the cutting orientation. It also has an LED light to illuminate your work area. Internal twin rails give stability and the ability to work with the back of the machine against a wall, ideal for your home garage.

Ryobi EMS254L 2000W 254mm Compact Sliding Mitre Saw

The Ryobi compact mitre saw is ideal for multiple applications, including cutting worktops, boards, decking and sheet materials. The saw is surprisingly compact and lightweight and benefits from forward sliding bars, allowing you to work against a wall.

This saw benefits from 50° left and right mitre bevel capacity from -2° to 47°. As well as being compact in size, it is versatile. Its extra-wide side extensions provide support for any work with timber, and the 2,000W motor provides up to 4,500rpm for seamless cutting.

Safety features include the ‘Lock-On’ switch and the Live Tool indicator, which shows the saw is plugged into the power supply.

Milwaukee M18FMS254-0 18V 254mm Fuel Mitre

With the steel detent plate, this mitre saw is a tool that can cut up to 307 cuts in 38mm x 89mm soft wood accurately and repeatedly. The Milwaukee saw has a 254mm blade, delivering large and accurate cut capacities, and the motor gives you up to 2x longer life and 25% more power than a standard mitre saw.

The large sliding fences provide maximum support to the materials that are being cut. In addition, these fences provide accuracy and stability.

The REDLINK PLUS intelligence system stops the tool and battery overloading and also uses a lithium-ion battery pack, which gives the user up to 2.5x more run time, 20% more power and up to 2x more battery life.

Milwaukee M18SMS216-0 18V 216mm Slide Mitre Saw

This Milwaukee slide mitre saw has a 216mm blade paired with an incredible 2,700rpm motor, providing fast and accurate cutting power. The Fine Adjust with Detent Override makes it simple to create precise mitre angles and the heavy duty cast base offers durability and accuracy, thanks to fence and dual vertical steel rails with linear bearings that deliver a smooth sliding action.

To cut lines perfectly and quickly, the mitre saw is fitted with an adjustable laser. You can achieve repeat accurate cuts using the steel detent plate with pre-set angles. This can be used alongside the lock lever/ handle overmold, which reduces fatigue and maximises comfort for you.

The saw has a 48°/-2° bevel capacity and a mitre saw release system for a quick and smooth change of the cutting orientation. This mitre saw tool also has an LED light to illuminate your work area.

Table Saw and Stand

A table saw (also known as a saw-bench), while similar to a mitre saw, is perfect for cutting plywood sheets. This is because it doesn’t have the same depth limitations that you’ll experience with a mitre saw.

You can use a table saw to cut lumber, however if you’re working with material that’s on the thicker side, you may find you have to adjust the blade height to make sure it goes all the way through. Usually, once you have made this adjustment, you’ll find cutting to be smooth.

Table saws can make your work much more clean-cut and precise, which makes measuring for your projects and fitting the pieces together later on a much easier task.

Milwaukee M18FTS210-B Table Saw with One-Key

This table saw generates the power to cut 190 metres of 19mm OSB board on one 12.0 Ah battery charge. An all-metal frame provides durability for daily job site use.

This is the industry’s first table saw that wirelessly connects to a smartphone to track and manage a tool’s performance and location, making it a smart option for a construction task.

Milwaukee TSS1000 Saw Stand

This saw stand is designed to be used with the Milwaukee M18FTS210 table saw. The portable folding stand features a steel construction to handle the conditions of a jobsite. At 6.6kg, it’s lightweight, making it easy to transport.

For added safety, quick-release brackets hold the saw firmly in place, removing any possibility of movement while cutting.

Get in touch

Now you know what size mitre saw you need, what the different types are and how to approach buying a mitre saw, hopefully you feel ready to go ahead and get to work. If you have any questions, feel free to contact us. Our in-house experts are always on hand to offer advice and help with your queries.

Call SGS on 01332 576 850 or fill out our contact form today.